1. LNG System

LNG System is a program developed by utilizing the LUSAS Programmable Interface (LPI) of the general purpose structural analysis program LUSAS (London University Structural Analysis, UK), based on the experience of performing LNG tank analysis and design projects over the past two decades, and is a software that implements automation in the process of building analysis models and performing design reviews for LNG storage tank design.

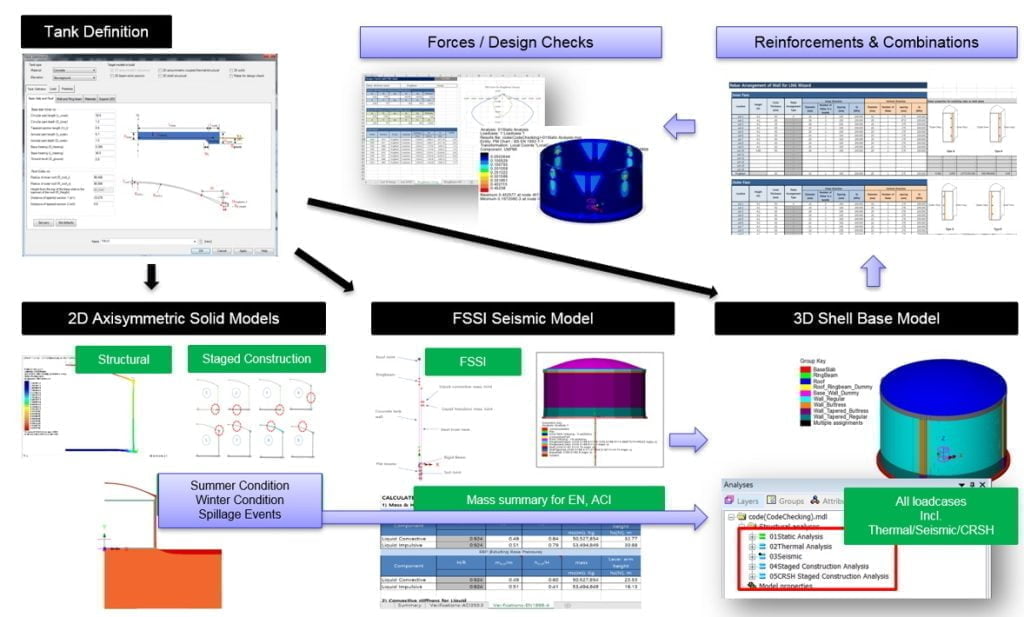

The information for the target tank design is centrally managed in the Tank Definition. The tool automatically constructs models for 2D/3D, static/dynamic/seismic/construction stage/creep shrinkage analyses. It extracts section forces, performs design reviews based on reinforcement details, and generates reports.

2. Feature Summary

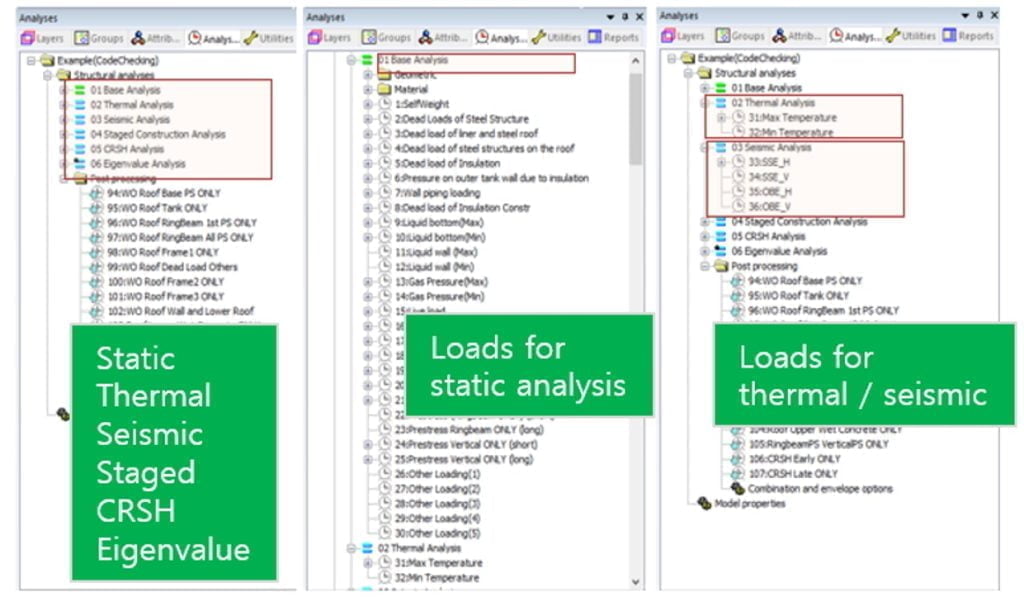

– Build analysis models: two- and three-dimensional, static, dynamic, and construction-phase analysis models.

– Extraction of section force: Extraction of section force by direction required for Roof / Wall / Slab respectively

– Load Combination: Load Combination using Excel Template

– Rebar and Tendons: Rebar/Tendon Placement with Excel Template

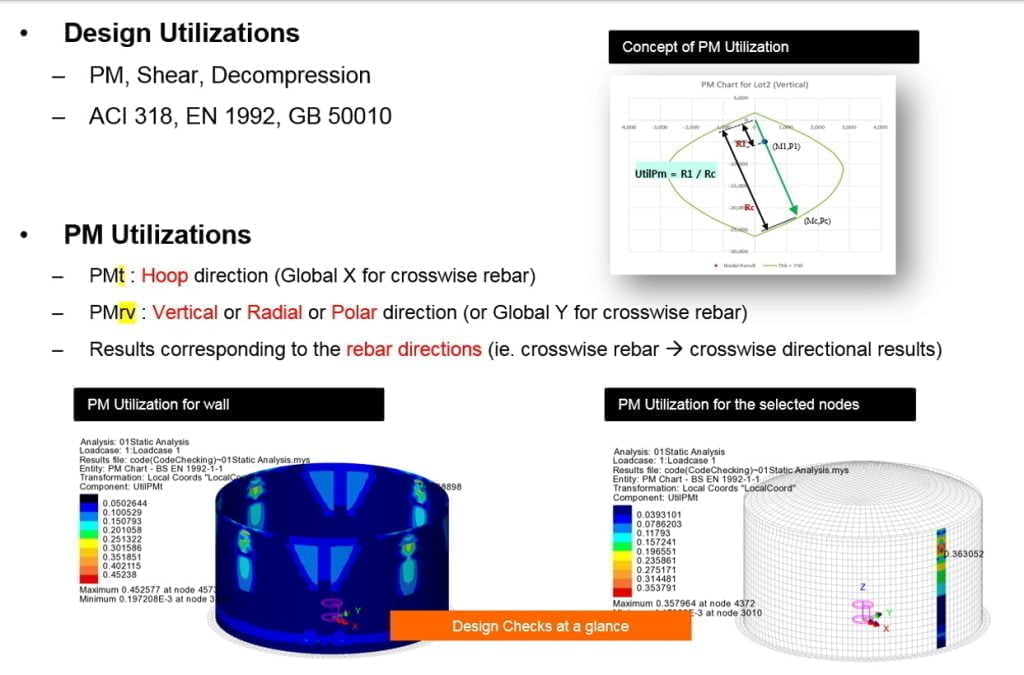

– Design Review GUI: Design review results based on ACI / EN / GB codes are expressed in a GUI.

– Design Review Report: Organize design review results based on ACI / EN / GB codes into an Excel report.

3. Expectation Benefit

– Minimize user errors during analysis model creation and results extraction

– Quickly extract design review results (GUI/reports) and modify the design

– Reduce design review time/effort → Free up time for design optimization

4. Ideas and Features

(1) Combination of thermal + structural loads

Thermal analysis is essential for tanks that hold liquids at low temperatures.

For thermal analysis, it is necessary to use a model with Solid elements to represent the thickness of the cross-section, but it is very time-consuming and expensive to use all Solid elements for the analysis to evaluate the effects of other structural loads, so in practice, we use a model with Shell elements.

In this case, the design load combination of the results obtained from the model using solid elements and the model using shell elements cannot be performed in a general structural analysis program, so load combination and design review are often performed using Excel or database tools, and it is difficult to respond quickly to changes that occur during the design process.

LNG System integrates thermal analysis, static analysis, dynamic analysis, and step-by-step analysis in a single model, allowing you to perform load combinations and design reviews in a GUI environment.

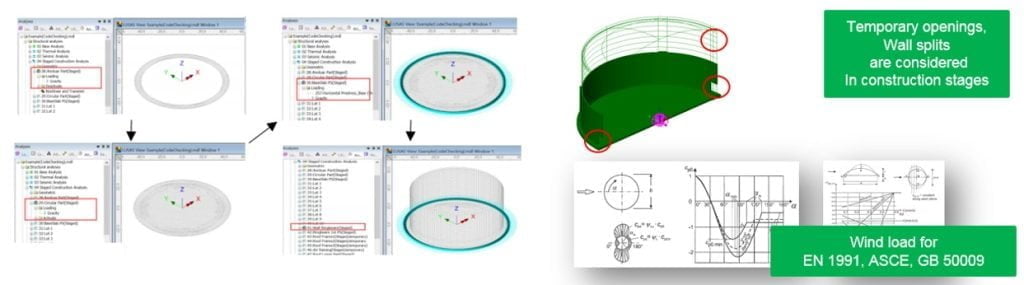

(2) Analysis and prestressing by construction phase

Depending on the design environment, various types of construction sequences are reviewed, and in this process, prestress in particular must be applied differently depending on the existence of temporary openings, and may be partially introduced (e.g., ringbeam prestress is introduced at 50% and 100% after the roof is poured), and there are many changes such as reviewing short-term prestress and long-term prestress separately, so much attention is required for modeling modification and design review.

LNG System automates the process of building an analysis model for each stage of construction considering various construction sequences, such as before and after the temporary opening and closure, and provides a UI that allows you to easily adjust the construction sequence if necessary.

(3) Convert results by rebar reinforcement direction

In order to extract the analysis results of the circular tank structure in the direction of rebar reinforcement and perform design review, it is necessary to convert the result direction according to the Cylindrical Local Coordinate and Spherical Local Coordinate System in the direction of Radial / Hoop for Slab, Hoop / Vertical for Wall, and Meridional / Hoop for Roof. Also, Slab has a mix of crosswise and circumferential roots, which adds to the complexity.

LNG System automates the design review process by outputting results by direction according to the structural part and the direction of rebar reinforcement.